The fusion of classic elegance and modern technology is not only reflected in our New-Tech series models. In our workshop, we also utilise modern technologies in combination with the craftsmanship of our specialist team. At Mechatronik, we combine tradition with innovation to create unique automotive experiences.

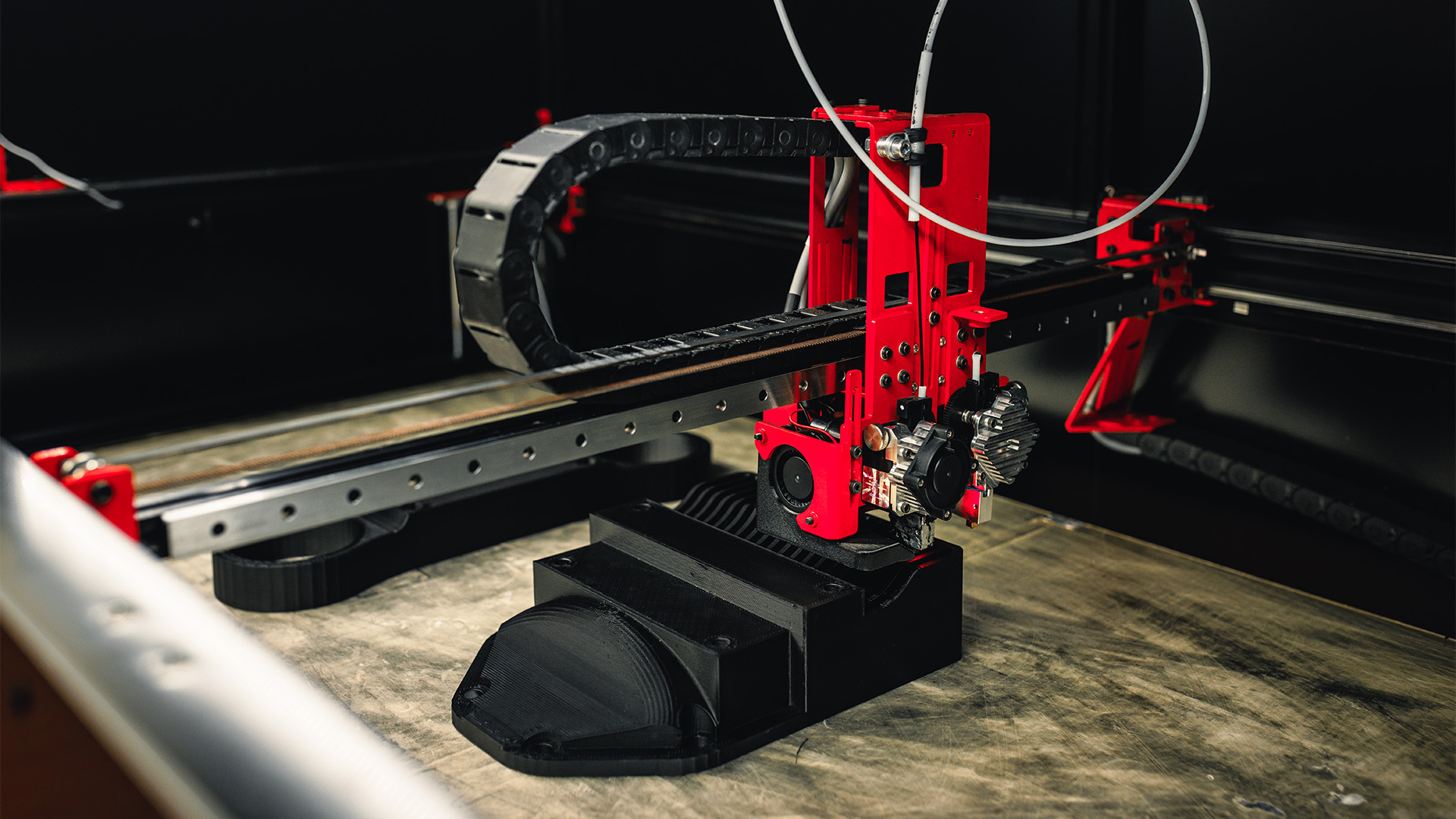

When restoring classic vehicles, we use 3D printing to reproduce parts. These are often difficult to obtain or no longer available on the market. This independence from parts availability means we can minimise delays in restoration and ensure restoration projects are completed on time. Another important aspect is the repair and maintenance of the legendary Mercedes-Benz CLK GTR. As only 25 vehicles were produced, many parts made specifically for this model series are no longer available. Even in our extensive CLK GTR spare parts inventory, we cannot find all spare parts. By using 3D-printed parts, we can preserve authenticity while ensuring that these iconic vehicles remain in the best possible condition for the future.

We also rely on components designed and manufactured in-house for the series production of our New Tech Series models. We manufacture a variety of brackets and covers ourselves, which are concealed under the beautiful bodywork of the cars. Our use of 3D printing technology also extends to prototyping, particularly in the ongoing development of our New Tech Series models. Here, 3D printed parts play a crucial role in ensuring that newly designed components fit perfectly before we go into series production. Thanks to 3D printing, we can carry out precise pre-testing to ensure the highest quality.

The state-of-the-art 3D printers are versatile and can process a variety of resins and plastics. This versatility allows us to produce customised solutions for every vehicle and every requirement.